Manipulator e thusoang ke matla e boetse e bitsoa pneumatic balance power-assisted manipulator, crane ea pneumatic balance, le booster balance. Ke sesebelisoa sa morao-rao se thusoang ke matla se sebelisetsoang ts'ebetso ea ho boloka basebetsi nakong ea ho sebetsana le ho kenya thepa. Ke mochine o thusang ka pneumatically, o sebetsang ka letsoho. Tšebeliso ea li-manipulator tse thusoang ke matla e ka fokotsa matla a basebetsi, ea finyella ts'ebetso e bobebe le boemo bo nepahetseng ha u sebetsana le lisebelisoa tse boima tsa mosebetsi, le ho netefatsa polokeho ea lisebelisoa le basebetsi. Manipulator a thusoang ke matla a sebelisoa haholo-holo ho thusa basebetsi ho sebetsana le ho kopanya, 'me ke sesebelisoa sa ho sebetsana le matla se fokotsang matla a mosebetsi. E kopanya melao-motheo ea ergonomic mme e fana ka lipalangoang tsa thepa, ho sebetsana le lisebelisoa tsa mosebetsi le kopano le likhopolo tsa polokeho, bonolo, bokhoni le ho boloka matla. Nakong ea ts'ebetso ea lipalangoang, thepa e laoloa ke potoloho ea moea e utloahalang, e fetolang boima ba ntho e boima ka boeona hore e be matla a manyenyane a sebetsang ka letsoho, ho lemoha habonolo motsamao, lipalangoang le kopano ea lintho tse boima sebakeng leha e le sefe sebakeng sa ts'ebetso, le ho rarolla bothata ba lipalangoang tsa indasteri le kopano ka mokhoa o sireletsehileng le ka katleho. Lisebelisoa tse sa tloaelehang tse hlophisitsoeng li ka phethela liketso tse joalo ka ho ts'oara, ho tsamaisa, ho phethola, ho phahamisa le ho emisa lisebelisoa tsa ho sebetsa (lihlahisoa), le ho kopanya lintho tse boima kapele le ka nepo libakeng tse behiloeng esale pele. Li loketse ho kenya le ho theola thepa le kopano ea tlhahiso. Thepa e thusoang ke matla e ka boloka mosebetsi le ho ntlafatsa katleho ea feme.

Manipulator e thusang ka letsoho le thata e na le mochine o leka-lekaneng, sesebelisoa sa ho tšoara, le mohaho oa ho kenya. E ka leka-lekanya boima bo fapaneng ho tloha ho 20 ho isa ho 300kg mme e loketse ts'ebetso ea phetisetso ea thepa. Litšobotsi tsa ho leka-lekana ka botlalo le motsamao o boreleli li lumella opareitara hore a tsebe ho sebetsana le li-workpiece, ho beha maemo, kopano le lits'ebetso tse ling habonolo. E na le botsitso bo phahameng, ts'ebetso e bonolo, ts'ebetso e phahameng, ts'ebetso e phahameng ea ts'ireletso, 'me e na le sesebelisoa se sireletsang khase ea khase. Likarolo tse kholo kaofela li entsoe ka lihlahisoa tse tsebahalang lefatšeng ka bophara, 'me boleng bo tiisitsoe. E na le ts'ebetso e felletseng ea ho emisa mme e bonolo ho e sebetsa; e entsoe ho latela melao-motheo ea ergonomic, e bonolo ebile e bonolo ho sebetsa; moralo oa sebopeho ke modular le taolo ea potoloho ea moea e kopantsoe; litšenyehelo tsa basebetsi li fokotsehile ka 50%, matla a mosebetsi a fokotsehile ka 85%, 'me katleho ea tlhahiso e eketseha ka 50%; ho latela mojaro le setorouku, li hlophisitsoe 'me li tla ka mefuta e fapaneng ho fihlela litlhoko tse fapaneng. Boholo ba ts'ebeliso ea li-manipulators tse thusoang ke matla: tse sebelisoang haholo ho kenya le ho laolla thepa indastering ea likoloi, indasteri ea lik'hemik'hale, liphutheloana tsa lihlahisoa, indasteri ea lisebelisoa tsa motlakase, indasteri ea thepa ea bohloeki ea ceramic, indasteri ea thepa ea moaho le thepa ea ka tlung, likarolo tsa tšepe, tlhahiso ea mochini le ts'ebetso, Mosebetsi o pheta-phetoang oa ho sebetsana le maemo a phahameng, indasteri ea matla a khase ea tlhaho le peterole, betri e ncha ea matla, thepa e ikemetseng le liindasteri tse ling, tse nang le li-grippers tse fapaneng, e khona ho hlokomela ho ts'oaroa le ho ts'oaroa ha lihlahisoa tsa libopeho tse fapaneng liindastering tse fapaneng.

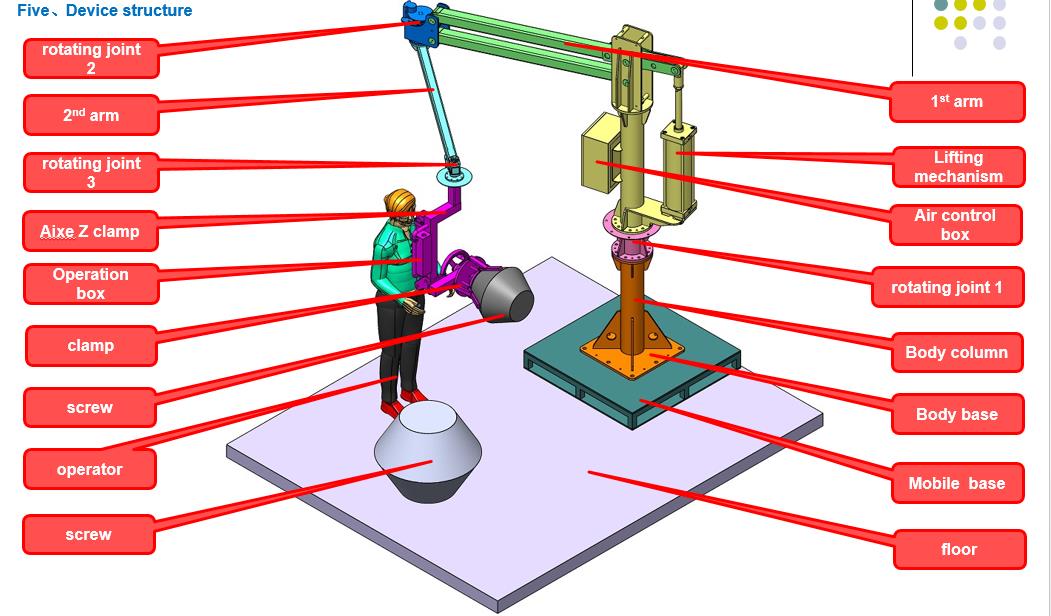

Sesebelisoa sena sa manipulator se thusoang ke matla se na le setsi se tsitsitseng, kholomo ea 'mele, cantilever e kopantsoeng, mochine oa ho phahamisa, mochine oa Z-axis, molamu oa ts'ebetso le likarolo tse ling tsa mochine. Opereishene e tsamaisa manipulator e thusoang ke matla ho electrode ea graphite. Opareitara e suthisetsa sebapi sa manipulator se thusitsoeng ke matla fatše ho tšoara sekoti sa graphite electrode. Ka mor'a ho e tšoara, e isoa boema-kepe ba graphite electrode, e fetotsoe ho feta likhato tse 90, 'me basebetsi ba tiisa likhoele tsa screw bakeng sa ho kopanya. Ha ho bapisoa le ho tšoara ka letsoho, sesebelisoa sena se na le matla a ho sebetsa a bobebe, lebelo la ts'ebetso le potlakileng, sebopeho se bonolo, sekhahla se tlase sa ho hloleha, tlhokomelo e bonolo, le litšenyehelo tse tlase tsa tlhokomelo. E sebetsa molao-motheo oa ho leka-lekanya matla ho lumella opareitara ho sutumetsa le ho hula lintho tse boima. E ka sisinyeha le ho ema ka mokhoa o leka-lekaneng sebakeng se lumellanang, haholo-holo se loketseng ho tšoara le ho pata li-workpieces tse nang le maemo a nepahetseng kapa litlhoko tsa kopano. Li sebelisoa ke liindasteri tse fapa-fapaneng ho fokotsa likotsi tsa morao tsa basebetsi le mokhathala, ha li ntse li ntlafatsa katleho ea tlhahiso le boleng. Li-manipulators le lisebelisoa li entsoe ka tloaelo le ho etsoa.

'Mele oa manipulator o entsoe ka profiles ea carbon steel. Bokaholimo bo fafatsoa ka phofshoana ea electrostatic mme e apehoa ka mocheso o phahameng. E na le botsoalle ho tikoloho, e ntle ebile ha e na kutu ho feta ho penta. Sistimi ea taolo e amohela konopo ea mochini oa li-valve + shift switch switch, e leng bonolo ho e sebetsa ebile e tsitsitse ho e ts'oara. Sebaka sa ho kopana le sehlahisoa se entsoe ka lisebelisoa tse seng tsa tšepe ho sireletsa sehlahisoa.

Opereishene e sebelisa forklift ho sutumelletsa manipulator e thusoang ke matla sebakeng sa kopano ea li-electrode tsa graphite bakeng sa ho lokisoa, e tsamaisa sekoaelo sa manipulator se thusoang ke matla ka holim'a sekoti fatše, se beha clamp fatše, se laola manipulator ho tiisa screw ka likonopo, e e isa ka lehlakoreng la lesoba le khole la graphite electrode, e phethola clamp, Lulakanya eleketrode ebe o e kenya, ebe opareitara ka letsoho e potoloha gripper clamp ho notlela screw ka electrode ea graphite. Ka mor'a ho notlela, bula clamp ka konopo ho lokolla screw, tsamaisa clamp fatše ka holim'a screw hape, phetla clamp ho khetha screw, ebe u fallela ho electrode e latelang ea graphite ho qala ho notlela...

Nako ea poso: Oct-11-2023